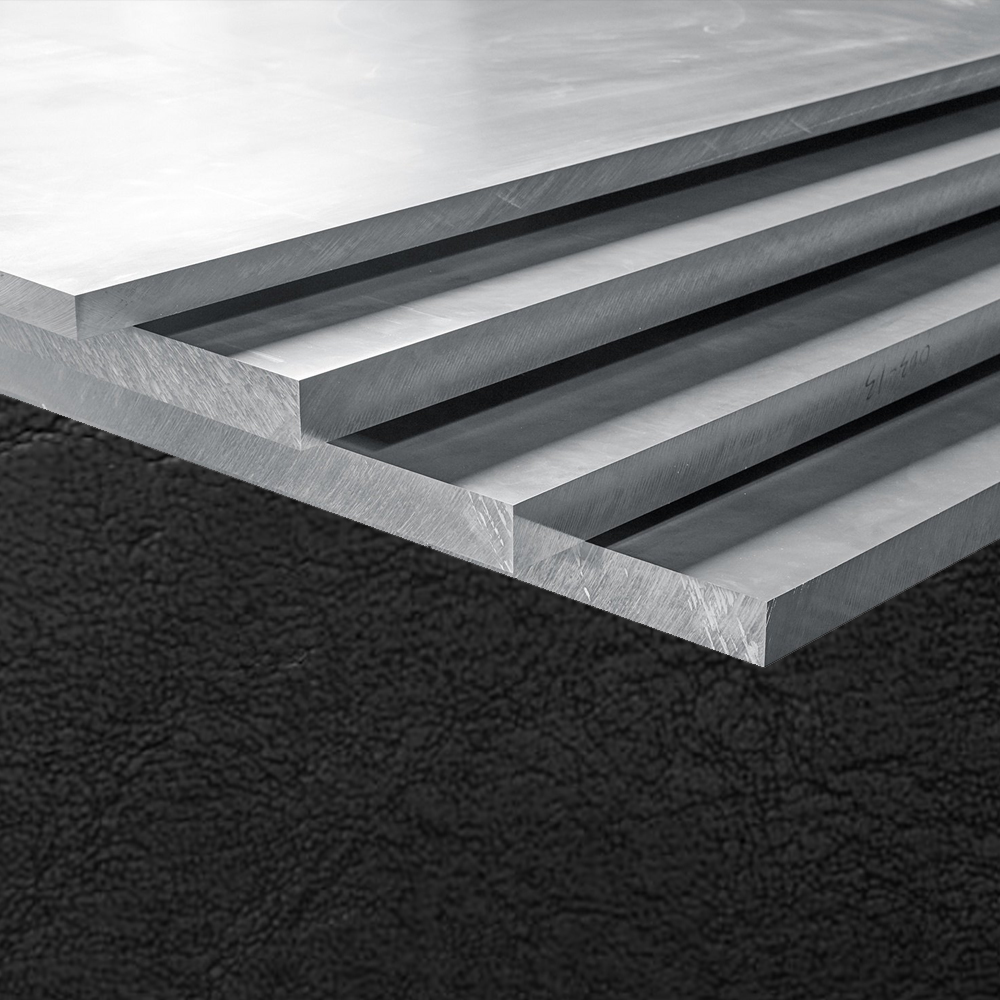

| Product Name | Length | Width | Thickness | Alloy |

|---|---|---|---|---|

| Aluminium Plate | ≥ 1000mm | ≥ 2000mm | ≥ 6mm | 6061 |

| Series | Alloying Element | Effect |

|---|---|---|

| 6XXX | Magnesium and Silicon Alloy | This combination provides excellent strength, weldability, and corrosion resistance. Commonly used in structural applications and extrusions. |

Only for Information*

More

Aluminium alloy 6061 stands as a testament to human ingenuity, combining the intrinsic qualities of aluminum with strategic alloying elements to create a versatile material renowned across industries. In the realm of international standardization, this alloy is famously recognized as “Aluminium Alloy 6061.” Its composition, comprising primarily aluminum, magnesium, and silicon, lends it a remarkable blend of strength, corrosion resistance, and formability.

Across the Atlantic, the American Society for Testing and Materials (ASTM) introduces us to “Aluminum Alloy 6061.” Employing a systematic four-digit numeric nomenclature, ASTM 6061 manifests as a versatile solution. The alloy’s first digit, “6,” signifies that it falls under the aluminum-magnesium-silicon series. It’s the amalgamation of these elements that imparts 6061 with its exceptional weldability and formability, rendering it indispensable for complex structures in both aerospace and automotive sectors.

In the British lexicon of standards, the British Standards Institution (BSI) extends a warm welcome to “Aluminium Alloy 6061.” While retaining the alloy’s core composition, the BSI classification system provides nuanced insights. This alloy, often referred to with the distinctive designation “H20,” signifies its utility in a plethora of architectural and structural applications. The British reverence for precision aligns perfectly with 6061’s outstanding machinability, making it an ideal candidate for various machining and fabrication processes.

Crossing borders to the east, the International Organization for Standardization (ISO) brings forth its take on the alloy: “Aluminium Alloy 6061.” ISO standards ensure international harmonization, and ISO 209 stands as a beacon of consistency, laying out the chemical composition of this alloy. From bustling industries to intricate craftsmanship, ISO 209 guides manufacturers and artisans alike in harnessing the properties of 6061 for their creative endeavors.

Venturing into the dynamic landscape of China, the alloy takes on an elemental alter ego – “Al-Si-Mg (6061) Alloy.” China National Standards (GB) give birth to a numeric denotation, GB/T 3190, encapsulating the alloy’s potential. This moniker resonates with its wide adoption in the country’s burgeoning aerospace and machinery sectors. Under the call of GB, 6061 readily assumes its role as a stalwart of innovation and structural prowess.

Across the European continent, the alloy presents itself with a distinguished demeanor – “EN AW-6061.” European Standards (EN) embrace alphanumeric clarity, and EN 573 stands as the cornerstone of aluminum nomenclature. Within this tapestry, EN AW-6061 emerges as a beacon of strength, harmonizing engineering marvels in industries spanning from architecture to marine applications.

In summary, Aluminium alloy 6061 is a global luminary in the realm of materials science, a versatile gem cherished by different standards under various monikers. Whether as “Aluminium Alloy 6061” in international contexts, “Aluminum Alloy 6061” in the United States, “Aluminium Alloy 6061” in British standards, Aluminium Alloy 64430 in Indian Standard or with its distinct identities in ISO, China, and Europe, this alloy’s impact is transcendent. It is a testament to human innovation and collaboration, shaping modernity through its unique blend of strength, weldability, and formability across a spectrum of industries and creative expressions.

Only for Information*